| FLY technologies is used for

coking and fouling liquid fuels, such as pyrolysis oil |

Clean

Fuels developed a new technology for feeding high-temperature

processes with pyrolysis oil (liquefied biomass) and other coking and

fouling fuels. Processes in which Free Fall Liquid Injection

Technology (FLY) can be applied include combustion for furnaces and

steam boilers, gasification, stationary engines and gas turbines.

Pyrolysis oil made from biomass is a liquid fuel that is known for

its coking character, which leads to strongly reduced plant

availability. Clean Fuels’s FLY technology effectively solves the

issue.

Coking

and fouling of liquid fuels is a result of the fuel's tendency at

elevated temperatures to form deposits on fuel lines, valves,

injectors, and reaction chamber surfaces. Particularly fuel injectors

are vulnerable to deposition of solid matter caused by auto-oxidation

(fouling) or cracking (coking).

Standard

solutions to this problem include nozzle cooling and flushing and

usually only postpone the occurrence of unacceptable levels of coking

and fouling. Clean Fuels’s FLY technology addresses the matter

from a couple of new angles: radiative heat transfer to injector

nozzles is minimised to maintain nozzle temperature below coking and

fouling point, the liquid enters the reactor in free fall without

touching any hot surface area, the fuel is evaporated rather than

atomised and any coke formation upon evaporation is converted with

separately applied reactants. To some extent, the technology shows

similarities with the well known Swedish Primus Stove, with its

liquid fuel vaporizer, known since 1892.

Clean

Fuels engaged in the development of FLY technology because reliable

technology for the combustion of biomass pyrolysis oil at small

scales in the range of 10-500 kW is not really available at

affordable costs.

Clean

Fuels developed, built and tested an 80 kW burner for fuelling with

pure plant oil (PPO) and pure biomass pyrolysis oil. Extended

combustion tests showed that the emissions to air are well below

limits allowable to the industry. The biomass pyrolysis oil used by

Clean Fuels was produced by Clean Fuels in its charcoal production

demonstration plant in Oldenzaal with a production capacity of 1.75

tonne charcoal per day.

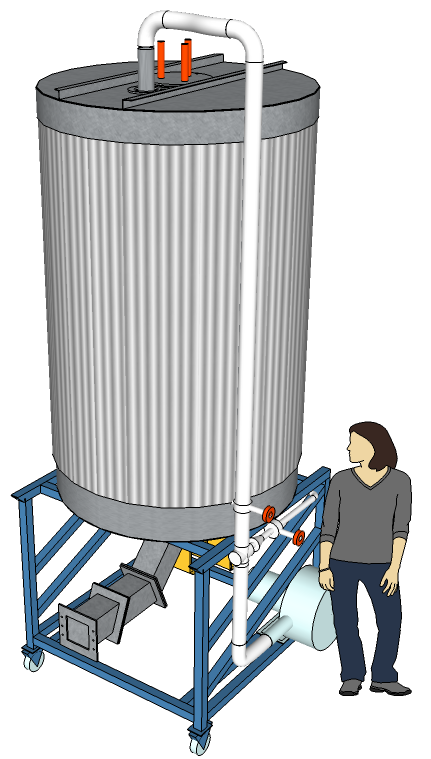

FLY

technology is also used by the same charcoal production facility.

Other uses that are technically feasible without substantial further

development include heating applications of 50-500 kW.

Patents

to Clean Fuels’s FLY technology are pending.

Oldenzaal,

26 March 2014 |

|

|